Our History

Family tradition from 1925 to today

The 1920s

Founding and development

After inheriting a plot of land in Borgholzhausen and erecting a factory building on it for the production of sausages, Richard and Elisabeth Beune founded the sausage factory in July 1925.

It all began with four pigs and four cows. The first animals were slaughtered on 21 July, Richard Beune having successfully acquired the first customers in the Ruhr area and Berlin. He and his wife Elisabeth Beune and brother Heinrich then worked steadily to expand the company. In 1927 Beune was to gain a new trading partner in the Düsseldorf company Reissert & Sohn, who then took care of sales of the sausage products in the Düsseldorf region. The site in Borgholzhausen was extended by buying adjacent plots, and the capacity of the factory was also expanded by the purchase of new machinery.

The 1930s

Production growth and wartime

Production continued to increase. Farmers’ mettwurst sausage was very popular, and sales by Reissert & Sohn were very successful. The installation of a diesel generator meant that the company could produce its own electricity for the factory. The Wehrmacht became interested in this, however, and demanded use of the generator for military purposes. A further hurdle in the 1930s was the increased rationing of food from 1936/37. Once the Second World War had broken out in 1939, meat was only available with ration cards or meat stamps. During the war, production was also limited by order to the production of spreadable cervelat sausage only. Staff became scarce, as all the young men in production and administration were conscripted into the armed forces.

The 1930s

Production growth and wartime

Production continued to increase. Farmers’ mettwurst sausage was very popular, and sales by Reissert & Sohn were very successful. The installation of a diesel generator meant that the company could produce its own electricity for the factory. The Wehrmacht became interested in this, however, and demanded use of the generator for military purposes. A further hurdle in the 1930s was the increased rationing of food from 1936/37. Once the Second World War had broken out in 1939, meat was only available with ration cards or meat stamps. During the war, production was also limited by order to the production of spreadable cervelat sausage only. Staff became scarce, as all the young men in production and administration were conscripted into the armed forces.

The 1940s

Necessity being the mother of invention, the company turned to geese and ducks

The next generation was gradually beginning to step up into their parents’ shoes in the company. Richard and Elisabeth Beune’s son Friedhelm returned from National Labour Service (‘Reichsarbeitsdienst’), obtained his school leaving certificate, and successfully passed the apprenticeship and journeyman examinations qualifying him as a merchant’s assistant in the company.

At this time it was necessary to be creative, as there was almost no meat available to buy. As demand was high, Richard Beune decided to slaughter and process ducks and geese. Turnover increased.

The 1950s

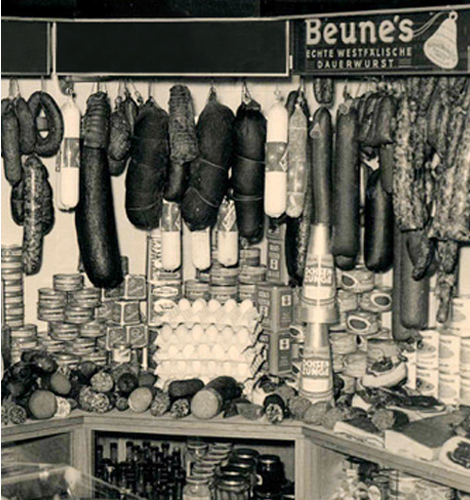

New factory and new products

At last there was pork and beef again, albeit in limited quantities. Production began again on a small scale.

In 1951, new production facilities were built in Borgholzhausen. The company also began producing sausages and parboiled sausages.

In 1959, Friedhelm Beune, son of the founders Richard and Elisabeth Beune, got married. From now on it was clear that the company needed to grow if it was to remain competitive.

The 1950s

New factory and new products

At last there was pork and beef again, albeit in limited quantities. Production began again on a small scale.

In 1951, new production facilities were built in Borgholzhausen. The company also began producing sausages and parboiled sausages.

In 1959, Friedhelm Beune, son of the founders Richard and Elisabeth Beune, got married. From now on it was clear that the company needed to grow if it was to remain competitive.

The 1960s

Packaged goods and new employees from elsewhere in Europe

No sooner said than done: in 1964, the first slicing and packaging machine was purchased. After some initial difficulties, the packaged goods began to become more and more popular. This led to a need to purchase more machines.

Housing had to be built in order to accommodate the increasing numbers of guest workers from Spain and Portugal, who had been coming to Borgholzhausen since 1961.

The 1970s

Economic upturn and further extensions

The 1970s saw various other conversion measures and more extensions. A social building was built in 1973. The production facilities were also extended. A new section for sliced meat was added, with two separate cold stores. In order to cope with increasing orders, even more new machines were purchased.

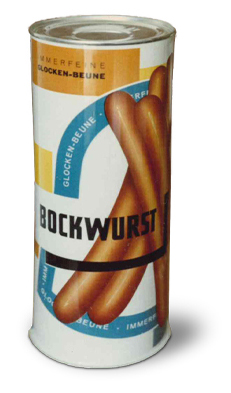

The range of products also continued to expand. What was in demand was sliced, pre-packaged goods and bacon; and ‘Bockwurst’, traditionally made from ground veal and pork, was also becoming more and more popular.

The 1970s

Economic upturn and further extensions

The 1970s saw various other conversion measures and more extensions. A social building was built in 1973. The production facilities were also extended. A new section for sliced meat was added, with two separate cold stores. In order to cope with increasing orders, even more new machines were purchased.

The range of products also continued to expand. What was in demand was sliced, pre-packaged goods and bacon; and ‘Bockwurst’, traditionally made from ground veal and pork, was also becoming more and more popular.

The 1980s

Change of generation: the second generation takes over

In 1983, the founder and owner Richard Beune died. His widow Elisabeth succeeded him in the management of the company, which she now shared with her son Friedhelm Beune.

The 1980s were a period characterised by a colourful, fast-paced way of life, with lots of new culinary trends. One success story of the 80s was the emergence of snack products. It was during this period that Glocken-Beune developed their first snack product, ‘Die Zwerge’ [‘the dwarves’] – predecessors of today’s mini-salamis.

The 1990s

Growth thanks to exports

On 8 May 1995, the company became an authorised EU processing plant without limitation. The first deliveries of products abroad followed, and the export business began to grow.

The 1990s

Growth thanks to exports

On 8 May 1995, the company became an authorised EU processing plant without limitation. The first deliveries of products abroad followed, and the export business began to grow.

The 2000s

‘Modern eating’

The BSE scandal led to a dramatic change in consumer behaviour. Beef products were no longer in demand. Once more, Glocken-Beune made a virtue out of necessity, and expanded its production. Producing vegetarian sliced loaf and spreads under the ‘Iss modern’ [‘Modern eating’] brand, the company came through the BSE crisis unscathed, without loss of turnover.

The 2010s

Award-winning energy concept

In 2013, the company won the Resource Efficiency Prize of the state of North Rhine-Westphalia. The prize was awarded for the planning, creation and implementation of an optimised energy concept based on thermal energy.

The 2020s

Brand relaunch for the future

In 2020, the entire Glocken-Beune range is being relaunched as a brand. The new product lines Beune’s Best, Ravensberger Land, Ready to Snack and Bacon have been created. The logo is being updated and the packaging redesigned.

The new look of our products brings Glocken-Beune in line with current food trends. The logo is also being retweaked and the website given a new, contemporary look. In the growing market for sausage and ham products, the Glocken-Beune brand is thus now ideally placed to respond to the challenges of the future.